Cold Room Panels

COLD ROOM PANELS

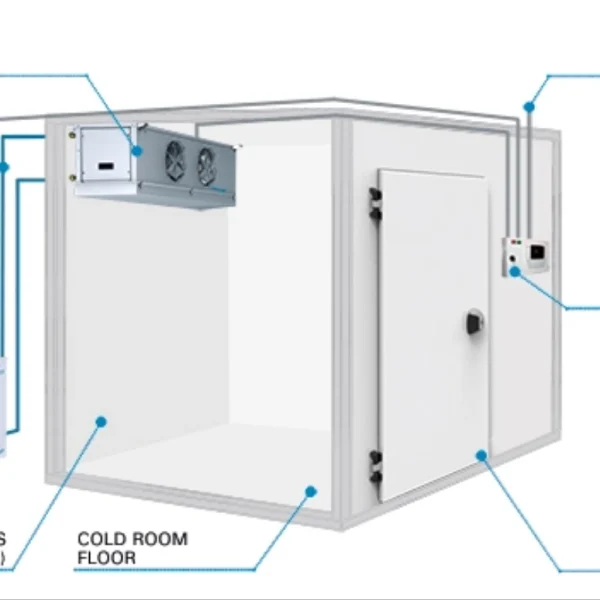

In this article, you will learn the specifics of choosing sandwich panels for refrigerating chambers made of polyurethane foam (PUR).

Most of the sandwich panels on the market are insulated with polyurethane foam (abbreviated as polyurethane foam or PUR) and metal sheathing on both sides. Also recently, polyisocyanurate foam (PIR) has become widespread. It has thermal insulation characteristics similar to polyurethane foam, but at the same time a higher degree of fire resistance, as a rule, EI30. It is possible to build fireproof partitions from PIR panels.

- Selection of panel thickness;

- Comparison of panels from different manufacturers.

Some manufacturers offer panels with expanded polystyrene insulation (EPS), which is also acceptable for thermal insulation of cold rooms, but since the thermal conductivity of the foam is about 1.5-2 times higher, then the panel thickness must be selected at least 20-30% more than for polyurethane foam sandwiches -panels.

Please note that mineral wool; basalt sandwich panels widely used in construction are not suitable for thermal insulation of refrigerating and freezing chambers due to their high moisture absorption. This leads to a rapid loss of the thermal insulation properties of the material because of moisture impregnation. In addition, the thermal insulation characteristics of mineral wool are significantly inferior to polyurethane foam.

When ordering heat-insulating sandwich panels, keep in mind that with small purchase volumes, you will be offered panels of standard length and, accordingly, you will need to buy sandwich panels, taking into account waste for cutting the panel for the dimensions of your chamber. When purchasing panels from several hundred sq.m. you can count on custom-made panels in the size you need, but the delivery time will be longer than when buying ready-made panels from a warehouse.

Selection of Panel Thickness

When choosing a panel thickness, it is important to consider several parameters:

Temperature difference – the maximum possible delta between the temperature inside and outside the chamber during operation;

Indoor humidity. In rooms with high humidity, the thickness of the thermal insulation must also be increased to prevent condensation on the surface of the panel.

The presence or absence of solar radiation, i.e. direct sunlight, such as outdoor installations, or direct sunlight through an indoor window.

A specialist, taking into account several more parameters, can do an accurate calculation of the required panel thickness for the refrigerating chamber but for ordinary, typical cases of storing products in a restaurant or store, you can focus on the following recommendations:

80mm panel is sufficient for cold storage (medium temperature storage range + 10 / -5 C),

Panels 100-120mm for the freezer (low temperature storage range -15 / -25 C).

As we have already noted above, for thermal insulation made of foam plastic, non-standard operating conditions, as well as for freezing chambers, the thickness of the thermal insulation is required more. In these cases, for the selection of the thickness of the sandwich panel, it is advisable to contact specialized refrigeration companies selling cold stores or sandwich panels.

Comparison of panels from Different Manufacturers

What you should pay attention to when buying sandwich panels:

- The type and thickness of the metal sheathing.

To reduce the cost of production, meeting the wishes of consumers, manufacturers offer panels with various types of cladding and metal thicknesses.

If price is a priority for you when choosing, then you can opt for a metal sheathing with a thickness of 0.5 mm. Manufacturers offer even less, but such products, as a result, have less rigidity and dents easily appear on them during installation and operation. Moreover, ceiling panels can bend. A good thickness for “work” with the panel during installation and long-term operation is the thickness of the metal 0.35-0.55 mm. Some, usually foreign manufacturers, offer panels with a thickness of 0.60-0.80 mm, but as a result, they are noticeably more expensive than the average price on the market.

In addition, the price of PPU panels depends on the quality of the metal. All panels are made of galvanized sheathing with various paints and varnishes, plasticizing and other types of coatings, on which the corrosion resistance and service life of the material depend.

Check the thickness of the metal and the type of panel coating when buying and comparing prices from different manufacturers in order to make an informed choice.

For additional savings, you can buy galvanized unpainted steel panels with metal sheathing. However, this is acceptable only for external cladding and only for installation inside dry rooms, the internal paneling of the panel must necessarily have a protective coating, since the humidity in the refrigerator is high, as a rule, at least 70%. This saving option is more suitable for “covering” a small room with sandwich panels. Nevertheless, the amount of savings will be insignificant.

- The quality of thermal insulation.

As we have already noted, the vast majority of sandwich panels for cold rooms, warehouses. They used with thermal insulation made of polyurethane foam or, a new material, polyisocyanurate, which has a high degree of fire resistance.

The quality of thermal insulation can be determined by the characteristic of its thermal conductivity, which fluctuates around 0.019-0.025 W * K / m for PUR. Accordingly, the lower this figure, the better the thermal insulation. For comparison, a cheaper material, expanded polystyrene insulation (EPS), has a thermal conductivity of 0.038 * K / m.

The structure of the polyurethane foam must be porous, uniform throughout the entire volume of the panel, without air bubbles.

Qualitative characteristics of the thermal insulation layer, which we recommend to pay attention to when purchasing moisture absorption, strength under mechanical loads and others, which you can clarify by requesting a test report from the product manufacturer or his dealer.

When installing a small chamber of an economy version on your own, these parameters may not be so important, but when ordering a medium-sized chamber (from 100 cubic meters), and even more so when building a cold storage, it is reasonable to approach the choice of sandwich panels with all care and attract specialists for consultations.

There are many details about the panels we produce. As the observers/experts who know them best in the field, of course, you have much experiences of the subjects. But we must say that we also have words to say.

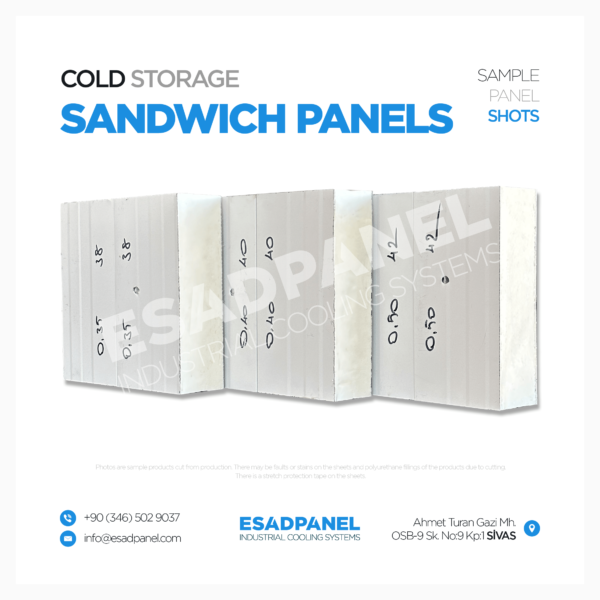

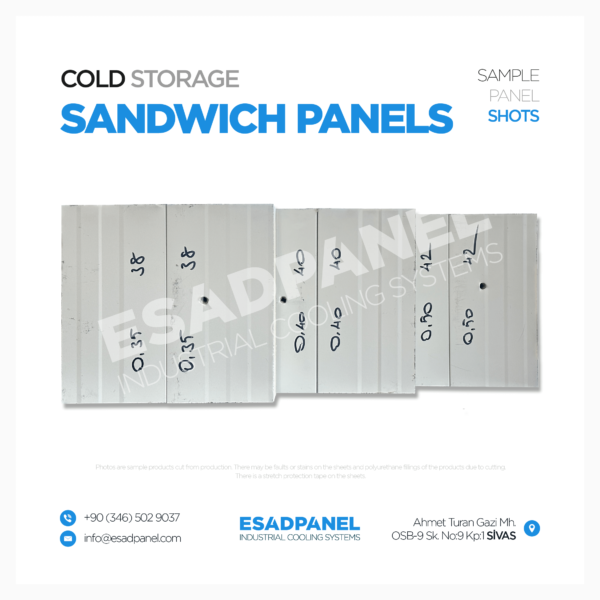

As you know, cold storage panels differ from ordinary sandwich panels with their polyurethane densities, sheet thickness and female/male lock details. In this sense, the most accurated features of a cold storage panel; 0.50-0.50 mm sheet thickness and 42 kg/m3.

As a result of the feedback we received from our clients; Although many companies specify such details in the cooling systems market, we also witness that some/many companies do not specify. Values such as 0.35-0.35 mm sheets & 38-40 kg/m3 density can be acceptable for panels in the end of the solution. However, values below 0.35mm sheet thickness (Example: 0.30 mm) and values below the polyurethane density of 38 kg/m3 (Example: 28 to 36 kg/m3) can unfortunately find a positive response to consumers or coolers/dealers. We do not manufacture such products. Because these products cause negative results and returns to both end consumers and salers/dealers in the long run, which unfortunately causes a great disappointment.

As Esadpanel; we’d love to produce the products that won’t cause “Consumer-Seller-Manufacturer” conflicts and deliver our labor to the people and solution partners who know the right and values of the goods; which products; that provides guarantee of -trust, gain and peace of heart.-

Fill the Form!

Write your needs and fill the form to contact us. Then get your cold room!