What Determines Cold Room Installation Costs?

❄️ What Determines Cold Room ? Installation Costs?

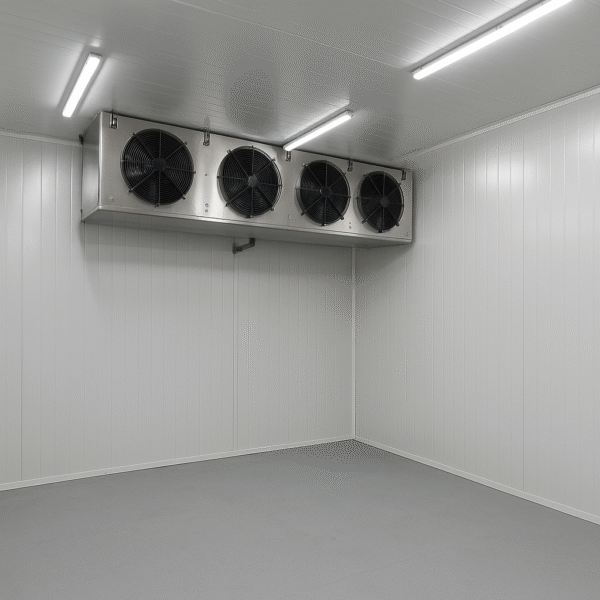

Cold rooms are essential for food, pharmaceutical, logistics, and various industrial sectors. However, one of the most common questions businesses ask is: “How much does it cost to install a cold room?” The answer is not straightforward—costs vary depending on several factors. Here's a breakdown of what influences cold room installation prices:

📏1. Size and Volume of Room System ?

The internal volume of the cold room (in cubic meters) directly affects the price. Larger rooms require more insulation panels, stronger cooling units, and more labor.

Small-scale rooms: 5–20 m³

Medium-scale rooms: 20–50 m³

Large storage rooms: 50+ m³

👉 The bigger the volume, the higher the cost.

❄️ 2. Cooling Type: Positive, Negative, Deep-Freezing or Blast Freezing?

Positive Cold Room: Typically +2°C to +8°C, suitable for storing fruits, vegetables, dairy products, beverages, and other fresh goods.

Negative Cold Room: Generally maintained at -18°C, ideal for frozen meat, poultry, seafood, and long-term storage.

Deep Freezing Rooms: Can reach down to -25°C, used for products that require deeper and more stable freezing conditions.

Blast Freezer (Shock Freezing) Rooms: Go as low as -40°C, designed for rapid freezing of products like meat, fish, or ready-to-eat meals to preserve quality and shelf life.

❗ Negative, deep-freezing, and blast freezing rooms are more expensive due to the need for stronger insulation, more powerful compressors, and higher energy efficiency components.

🧱 3. Panel Thickness, Insulation Quality & Material Standards

Panel thickness is a key factor in both thermal insulation and installation cost. The required thickness depends directly on the internal temperature of the cold room.

📊 Recommended Panel Thickness by Temperature:

| Internal Temperature | Recommended Panel Thickness |

|---|---|

| +5°C and above | 6 cm – 8 cm |

| +5°C to –5°C | 8 cm |

| –5°C to –18°C | 10 cm – 12 cm |

| –18°C to –25°C | 12 cm – 15 cm |

| Shock Freezer (–40°C) | 15 cm – 20 cm |

Thicker panels reduce thermal losses and are critical in negative and ultra-low temperature rooms such as deep-freezing and blast freezing chambers.

🧪 Polyurethane Foam Density: Why It Matters

The density of polyurethane insulation used inside the panel directly affects cooling performance and energy efficiency.

The optimal PU foam density is between 38–42 kg/m³.

At Esad Panel, we strictly do not recommend using panels with a density lower than 38 kg/m³ for cold room applications, as they compromise insulation and lead to higher energy consumption.

🛡️ Steel Sheet Thickness & External Durability

The thickness of the metal sheet used on the surface of the insulation panels is equally important for durability against physical and environmental impacts.

Minimum acceptable thickness: 0.35 mm

Standard option: 0.40 mm

Ideal choice for long-term use: 0.50 mm

Thicker sheets improve the panel’s resistance to dents, corrosion, and external wear, especially in commercial or industrial environments.

🧼 Corrosion Resistance & Hygiene Standards

When buying insulated panels, it is also crucial to evaluate the hygienic and anti-corrosive properties of the metal surface.

Panels should be coated with materials that are rust-resistant and antibacterial.

This is particularly important in industries such as food storage, meat processing, or pharmaceuticals, where hygiene regulations are strict.

👉 While these features may slightly increase the initial cost, they offer significant benefits in terms of safety, longevity, and compliance.

🚪 4. Door Type?

The type of cold room door significantly impacts both usability and cost:

Hinged door (standard)

Sliding door (more expensive, for large-scale operations)

Glass observation doors (used in retail or special conditions)

🔧5.Optional Add-ons and Accessories

Optional components that can increase the cost include:

Shelving systems

Temperature monitoring and control systems

Remote alarm and SMS alert systems

Humidity control units

These upgrades add professionalism and functionality but come at an additional cost.

🛠️ 6. Compressor Brands and Performance Differences

The compressor is the heart of your cold room, and its quality strongly influences both pricing and long-term reliability.

✅ Mid-Range Compressor Brands

Brands like Dorin, Tecumseh, and Frascold offer balanced performance and price. These are ideal for small to medium-sized cold rooms and are widely available in most markets.

Bitzer (Germany): Premium Quality

Bitzer (Germany): Premium Quality

Bitzer is considered the top-tier compressor brand globally. It offers:

Longest lifespan

Highest energy efficiency

Excellent long-term investment for heavy-duty and export-oriented facilities

Although Bitzer comes with a higher price tag, it pays off in reliability and reduced maintenance costs.

🔄 Hermetic vs Semi-Hermetic Compressors

Hermetic compressors are sealed, affordable, and used in compact systems. However, they cannot be repaired if damaged.

Semi-hermetic compressors are more expensive but repairable, and ideal for long-term commercial use.

Semi-hermetics can also include optional low-noise series, inverter drive, and advanced protection systems—features that add to the cost but greatly improve performance and energy efficiency.

📌 Final Thoughts: Always Go for a Custom Quote

Every cold room project is unique. Size, temperature needs, components, and location all shape the final cost.

📩 Share your project details with us, and we’ll prepare a personalized and competitive quote tailored to your business needs.