Fish Storage

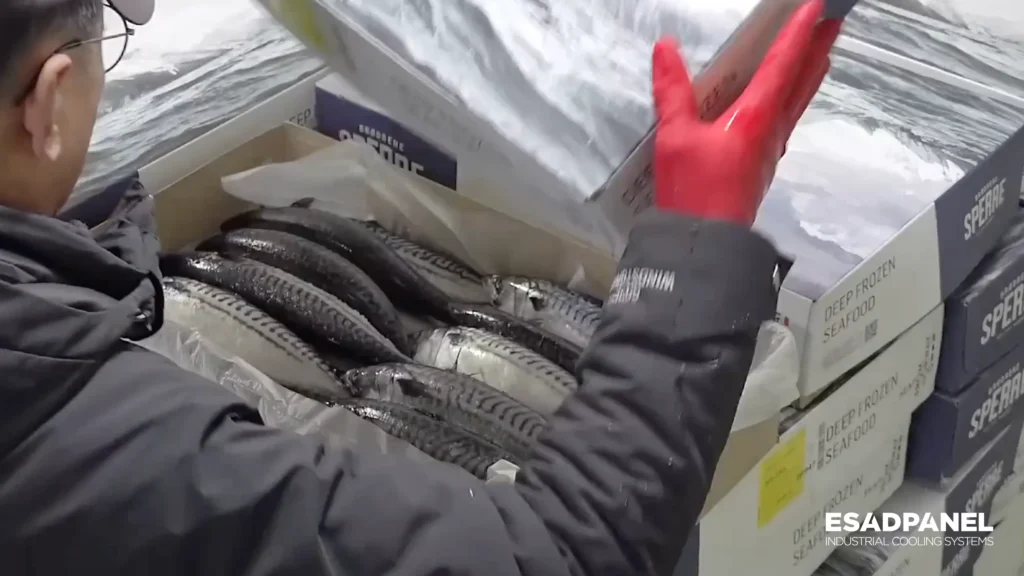

Frozen fish storage rooms, the final point of frozen fish products’ journey from the ocean, operate at negative temperatures. It is crucial that seafood be rapidly cooled before being stored, often at -40° blast freezer. Then storing in negative temperatures between -25°C and -30°C. It is critical that fish products harvested live from the sea enter the cooling chain within 24 hours.

The purpose of frozen fish storage is to ensure that products procured from fish processing facilities, either individually packaged or in bulk or boxed, are stored for extended periods, preserving their flavor and market value before reaching the end consumer in the market.

How Fish Storage Should Be?

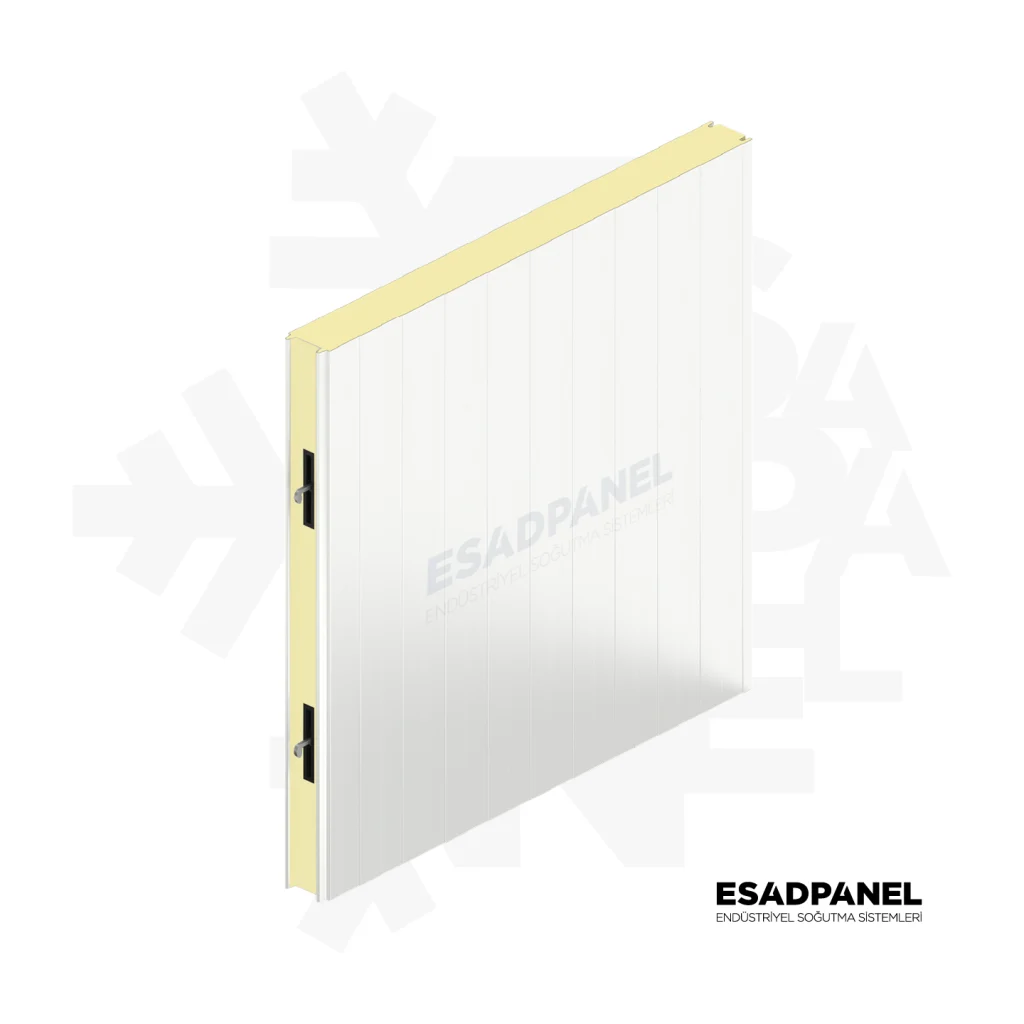

It’s absolutely crucial to consider these factors when purchasing a fish storage facility. Because fish products are seafood, they can contain water and salt. Because fish processing facilities remove corrosion-causing agents like water and salt from frozen products, fish cold storage doesn’t have to be constructed with stainless steel components like fish processing facilities. However, the potential for hygiene issues arising from seafood coming into contact with the fish cold room may necessitate the cold room being constructed with stainless steel components.

The fish cold room system works as follows: Products are brought to the facility on pallets and in cardboard boxes. Because seafood is a product, the boxes are packed in waterproof packaging. These fish boxes generally have standard dimensions: 40-50 cm wide, 50-70 cm long, and 13-17 cm high. These boxes allow for a frozen fish pallet to hold 800-1000 kg. The products are packaged and stored at a constant -25°C (-13°F) temperature. This allows for the storage of frozen fish in fish cold rooms for an average of 6-12 months, depending on the type of fish.

Another important factor in fish cold storage is having a proper storage plan. The first-in, first-out (FIFO) method is essential for long-term storage. This means that the fish stored first should also be the first to be shipped, ensuring products reach the market before their expiration date. For this reason, it is helpful to keep records of both the production date and the date the products enter the warehouse

-25°C

RECOMMENDED

TEMPERATURE

%90

REQUIRED

HUMIDITY

0.90

Kcal / Kg°C

COOLING TEMP°C

38.00

Kcal / Kg°C

FREEZING TEMP°C

2°C

GOODS OF

FREEZING HEAT°C

Above values may have some specific changes on type of product and desired solution. Contact with ESADPANEL for more.

After fish are collected from the sea, they are piled into large crates in designated areas at fish processing facilities. The fish are then separated into smaller crates and transported to washing areas in icy and cold water. There, a pre-cooling process is applied. After being washed with ice water, they are removed from a variety of substances, such as algae, sand, mud, blood, mucus, scales, or other marine organism residues. They are also treated with certain chemicals, such as sodium bisulfate or antioxidants. While the use of these substances is limited by food regulations, this process can extend the shelf life of seafood.

The fish are then filleted and separated from bones, fins, heads, tails, skin, and scales. The fish meat is then marinated. Transported in hygienic environments on stainless steel tray carts, the fish meat can then be subjected to IQF systems or rapid blast freezing. They can then be packaged in hygienic packaging or vacuum stretch wrap. After this stage, the fish are placed in appropriate boxes and the boxes are placed in frozen fish storage areas. Finally, it reaches the end consumer in markets or restaurants through the cold chain.

WHAT ESADPANEL OFFERS

As both a manufacturer and a project company, we can design and manufacture turnkey fish cold storage facilities tailored to your needs. We offer our valued customers a long-term, secure food storage system. We deliver turnkey solutions to businesses, which are key components of the food chain, using our own products and team. With global refrigeration after-sales service capabilities, we serve to Africa, Europe, Asia, and the America continents.

WORLDWIDE

SHIPPING

PROJECTS

TURNKEY

500m2 FISH STORAGE

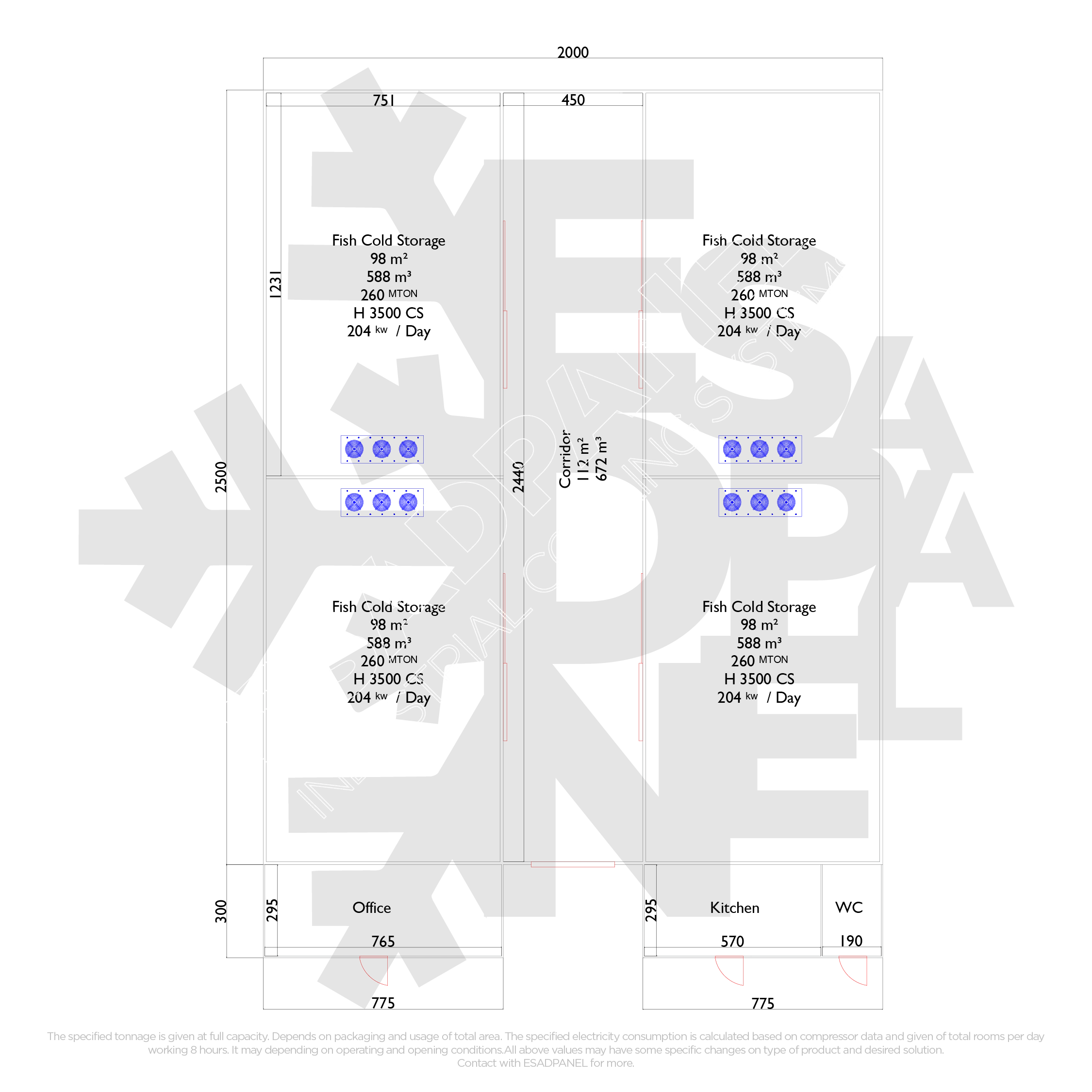

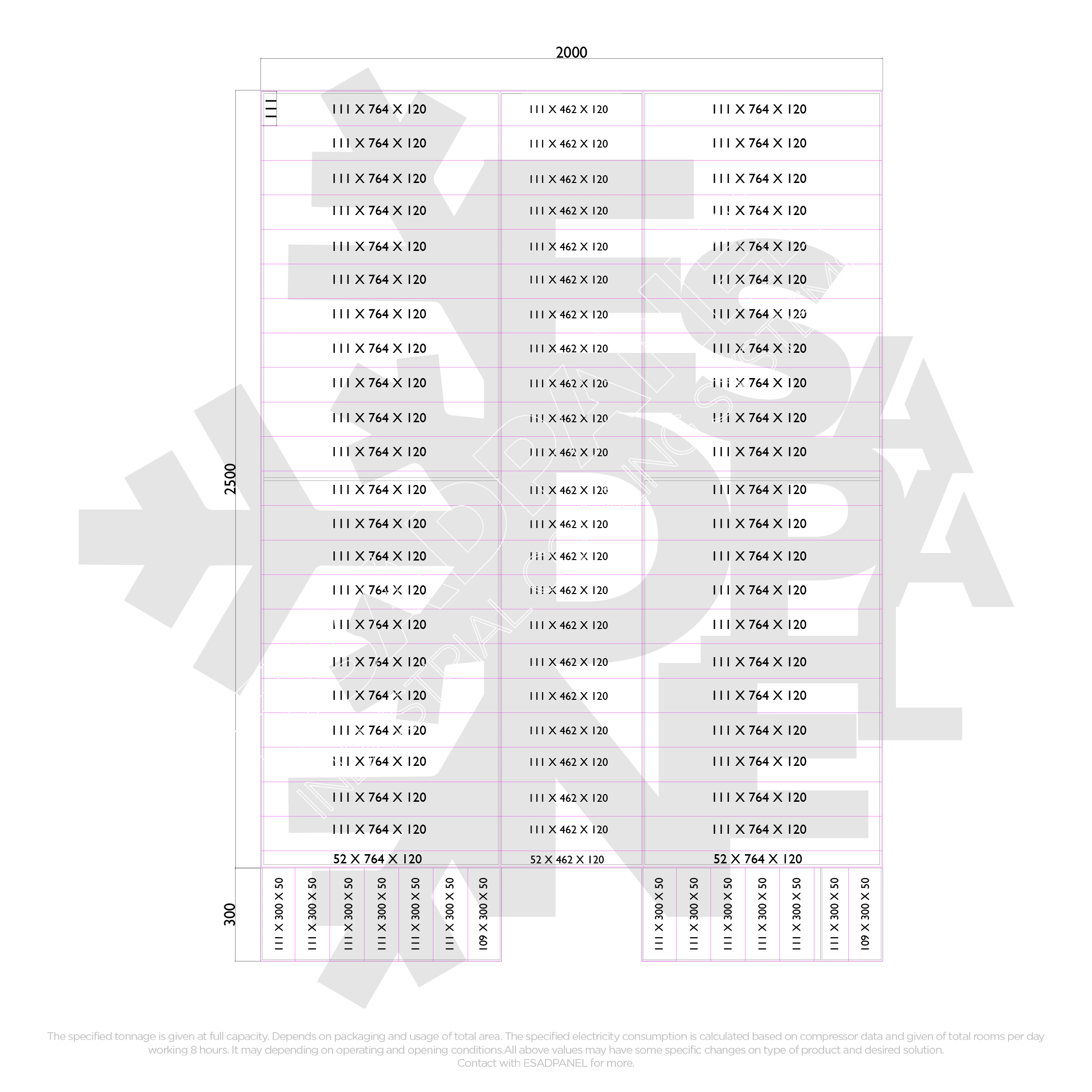

A cold storage facility is a profitable investment. Especially if you’re skilled in the field. If you have a large space and want to design a 500m² cold room facility to start, here’s a great idea. The technical drawings and 3D design below can help you achieve your dream.

Or, we can design a custom cold storage solution specifically for your existing space.

500 M2 FISH COLD ROOM

2D DRAWING

This is the fish cold room facility with the technical dimensions provided. The fish cold room above contains four different rooms. Each fish cold room has a capacity of 260 metric tons. The average daily electricity consumption is 202,4 kW. Each of these rooms is designed as 98 m² and 588 m³. The design includes a 4.5 m wide corridor for easy movement of loading and unloading equipment such as forklifts and pallet jacks. The facility also includes an office, kitchen, and WC for staff. Of course, there could even be a truck docking area and parking lot at the front. This is within our power to achieve by utilizing the available square meters.

500 M2 FISH COLD ROOM

3D RENDER

These images also show a 3D rendering of the existing plan. The cold rooms featured in the images are constructed with polyurethane-filled cold room panels and cold storage doors. Panel thicknesses can be customized from 5cm to 20cm, depending on the project. For fish rooms, 12-15cm panels are sufficient. Furthermore, the condenser units and evaporators were specifically selected for fish cold storage. Humidifiers and damper air climate/ventilation systems have created a long-lasting fish cold room capable of storing fishes with covering market value and fresh fishes.

-25°C

WORKING

TEMPERATURE

1040

TONNAGE

CAPACITY

1626

M2 OF

PANELS

BRAND OF

COMPRESSORS

816 kW

CONSUMPTION OF

ENERGY

The specified tonnage is given at full capacity. Depends on packaging and usage of total area. The specified electricity consumption is calculated based on compressor data and given of total rooms per day working 8 hours. It may depending on operating and opening conditions.All above values may have some specific changes on type of product and desired solution. Contact with ESADPANEL for more.

FISH PROCESSING PLANT

Fish processing facilities can include both ultra-professional facilities and standard processing facilities. Today, it’s possible to descale, fillet, and cut off the heads and tails of fish on automated conveyor lines. Hygienic standards in facilities are paramount, in accordance with food regulations. Therefore, the use of stainless steel products is crucial, as are hygienic PVC and plastic components. These facilities are virtually awash in water and salt. Furthermore, the fish’s internal organs and microorganisms are highly conducive to bacterial growth. It’s crucial that personnel and equipment within the facility are meticulously and hygienically maintained. Fish processing facilities have washing, pre-cooling, blast–freezing rooms, IQF tunnels, filleting areas, and packing areas.

All contents above are presented for example purposes only.

1000m2 FISH STORAGE

There’s always a bigger option. If you need more tonnage in a cold storage facility, here’s a plan for a larger 1000m² cold room.

Frozen fishes can be stored in these rooms for extended periods, maintaining excellent market value.

We can even design a dedicated office, restroom, kitchen, accounting area, loading area, and parking spaces.

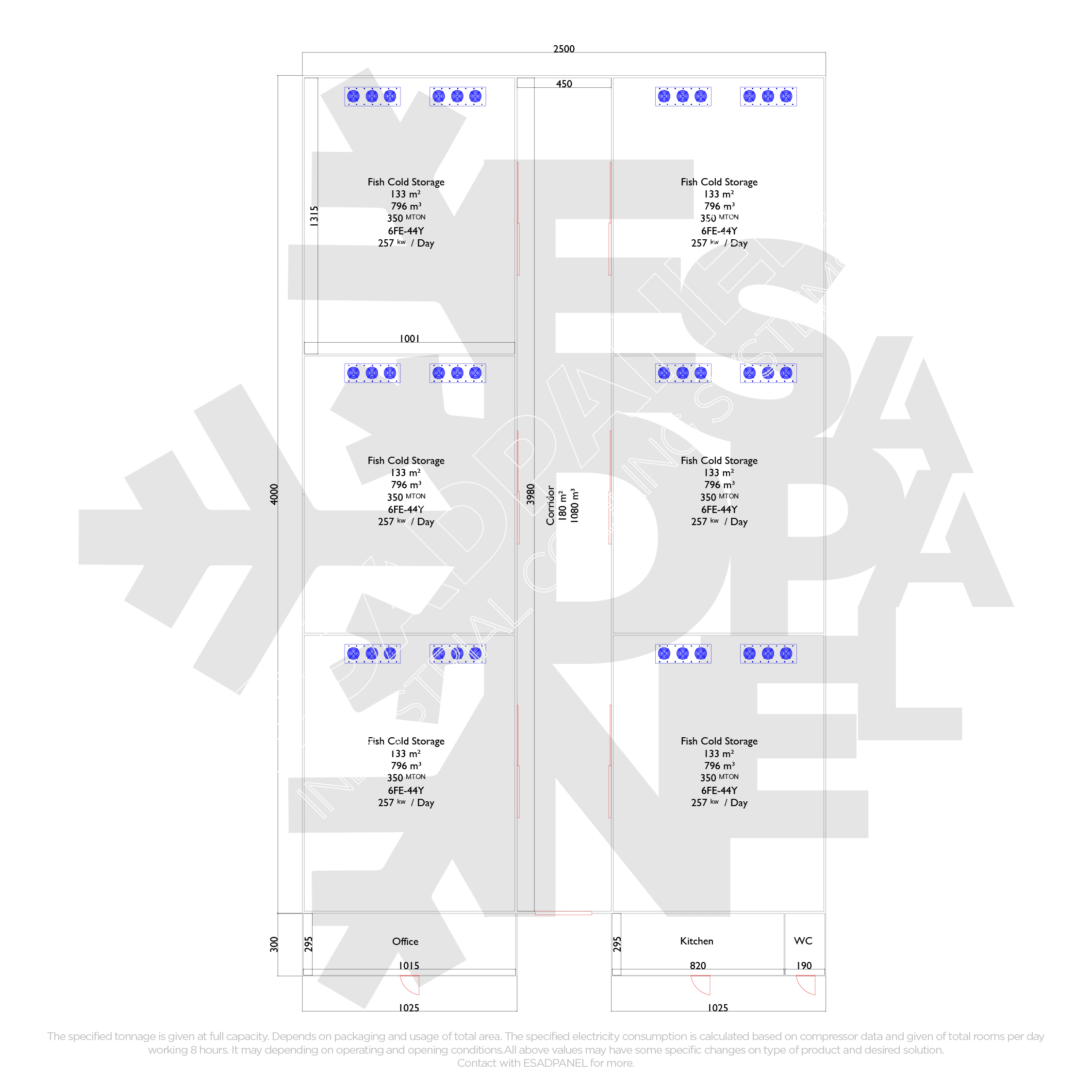

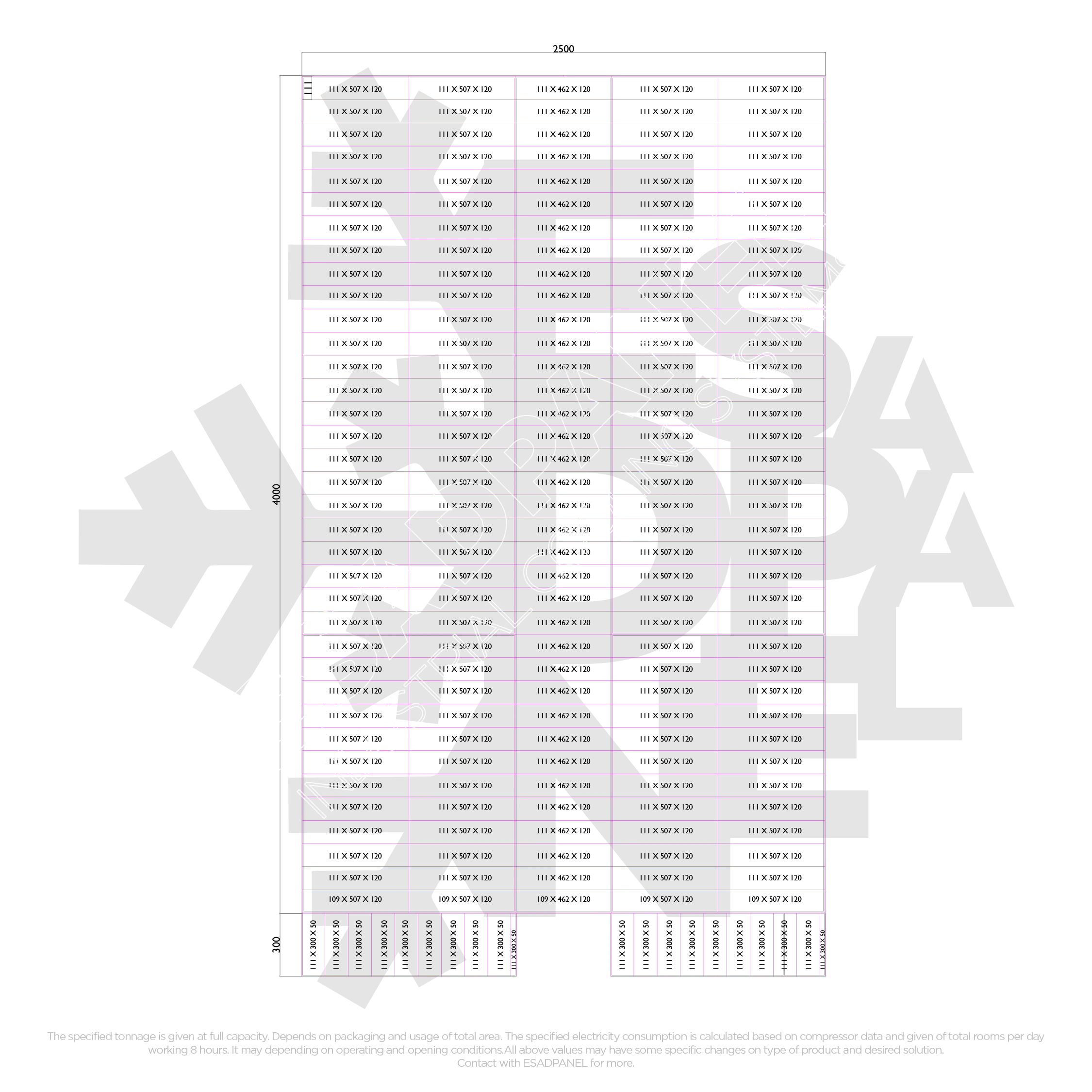

1000M2 FISH COLD ROOM

2D DRAWING

This is the fish cold room facility with the technical dimensions provided. The fish cold room above contains six different rooms. Each fish cold room has a capacity of 350 metric tons. The average daily electricity consumption is 257 kW. Each of these rooms is designed as 133 m² and 796 m³. The design includes a 4.5 m wide corridor for easy movement of loading and unloading equipment such as forklifts and pallet jacks. The facility also includes an office, kitchen, and WC for staff. Of course, there could even be a truck docking area and parking lot at the front. This is within our power to achieve by utilizing the available square meters.

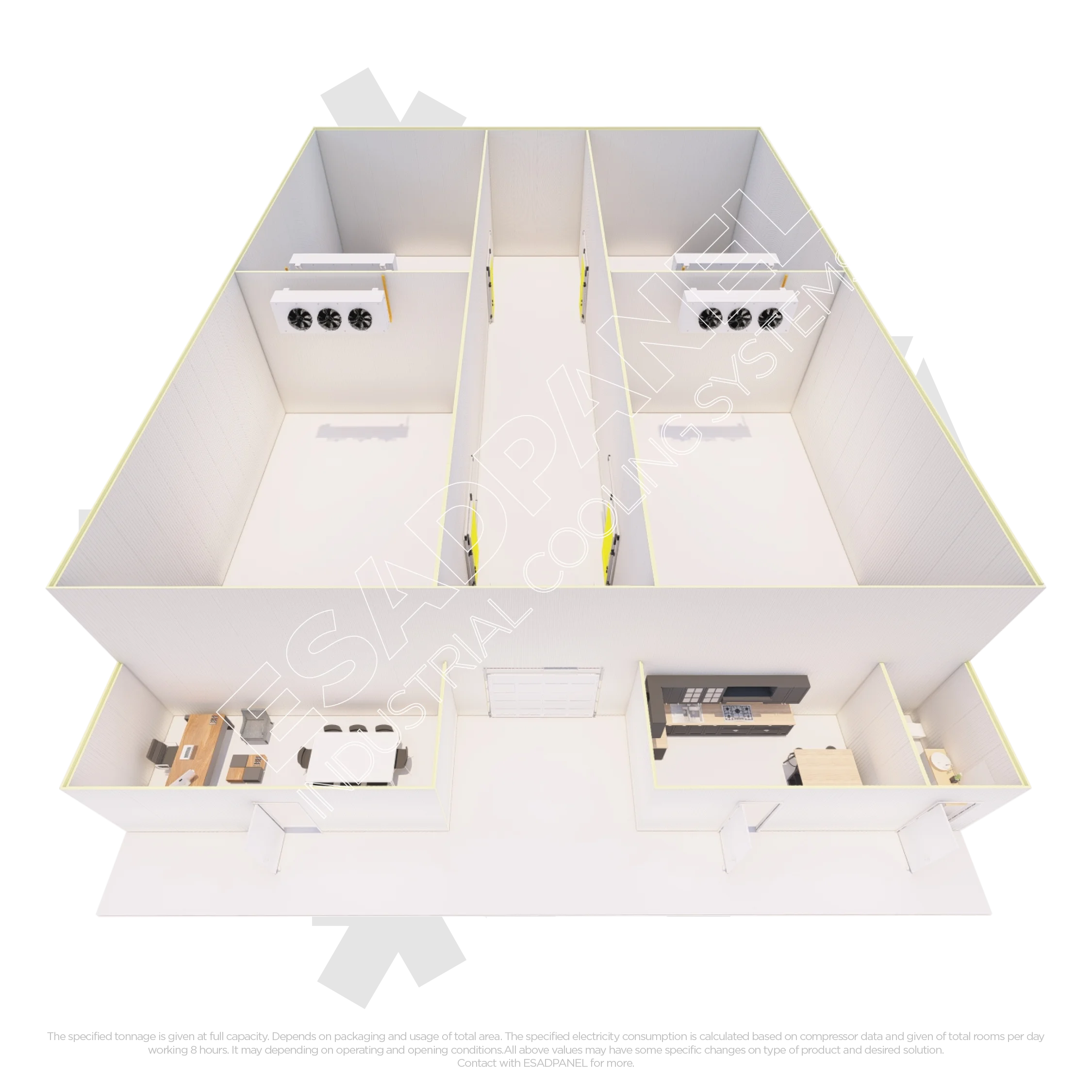

1000M2 FISH COLD ROOM

3D RENDER

These images also show a 3D rendering of the existing plan. The cold rooms featured in the images are constructed with polyurethane-filled cold room panels and cold storage doors. Panel thicknesses can be customized from 5cm to 20cm, depending on the project. For fish rooms, 12-15cm panels are sufficient. Furthermore, the condenser units and evaporators were specifically selected for fish cold storage. Refrigeration systems have created a long-lasting fish cold room capable of storing fishes with covering market value and fresh looking fishes.

-25°C

WORKING

TEMPERATURE

2100

TONNAGE

CAPACITY

2643

M2 OF

PANELS

BRAND OF

COMPRESSORS

1542kw

CONSUMPTION OF

ENERGY

The specified tonnage is given at full capacity. Depends on packaging and usage of total area. The specified electricity consumption is calculated based on compressor data and given of total rooms per day working 8 hours. It may depending on operating and opening conditions.All above values may have some specific changes on type of product and desired solution. Contact with ESADPANEL for more.

WE USE WORLDWIDE MATERIALS

With condenser units designed with components from world-renowned, reliable manufacturers, your cooling system is guaranteed long-term safety. The components we use in our products are available worldwide and are familiar to all refrigeration engineers and technicians.

LESS

GWP

PARTS OF

SPARE

AVAILABILITY OF

SERVICE

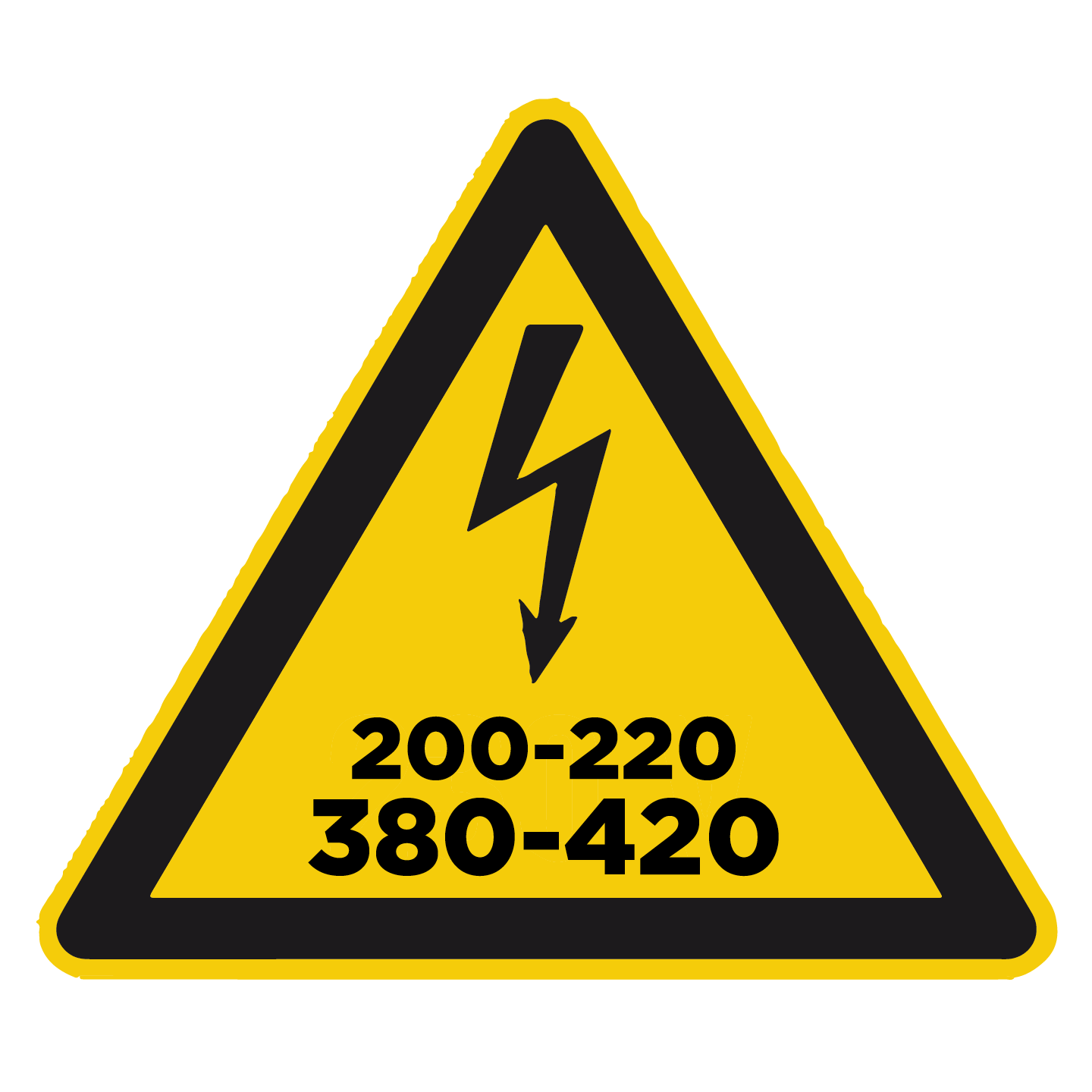

FOR MANY

POWER V/PH/HZ

We can design both economical and long-term systems based on the geographic location where the products will be used. We can adjust voltage, phase and hz values across a wide range of voltages, both single-phase and three-phase. We do provide it for USA, Europe and Asian markets too.

We also offer refrigerant options. While low-GWP gases can be used, common gases are also among our options.

SMALLER / LARGER

Larger or smaller, it doesn’t matter. A 10m³ cold room or a 10,000m³ cold storage is beyond the capacity of this factory. ESADPANEL is always at your service, providing the key to production with the features you desire and open to millions of customizations. Contact us for the design, production, and turnkey delivery of your cold storage facilities.