Apple Cold Room

Apples, known for their delicate and respirable characteristics, have many crucial elements in their cold chain from the field to the cold storage area. There are two types of apple cold room: professionally produced controlled atmosphere rooms and standard ventilation systems.

The goal of these rooms is to maintain the market value of apples and ensure a healthy fruit supply. Apple cold storage allows for long-term storage of apples, while preserving their moisture content, acidity, crispness, and the vibrant surface of their surface, which adds to their appearance.

How Apple Cold Room Should Be?

When purchasing an apple cold storage facility, it’s certainly crucial to consider these factors. Being an expert and experienced engineer isn’t enough. It’s crucial to understand the apple, the field, and experience the conditions. At ESADPANEL, we’re deeply involved in fruit and vegetable products. We’ve listened to our farmers, the most important elements of the supply chain. We’re meeting with fruit and vegetable producers and sharing these experiences with the world.

The system in apple cold room works as follows: Apples consumes oxygen, and from this oxygen, they produce carbon dioxide. This is a respiration process. Two factors come into play here: either respiration will be slowed, extending the apple’s storage life, or the carbon dioxide released by the apple’s respiration will be removed from the room and fresh air O2 will be brought in.

Both methods allow for the establishment of cold storage for apples. Atmosphere-controlled systems can extend storage life to 8-12 months, while standard damper-ventilated systems can extend apple storage to 3-4 months. The waste rate for both varies, ranging from 15% to 2%. Because the investment cost of CA systems is high, apple processing/production facilities generally use them for long-term post-harvest storage. For distributors and wholesalers, the “Ventilation System,” with its low investment cost and short-term storage, is more practical.

2°C

RECOMMENDED

TEMPERATURE

%90

REQUIRED

HUMIDITY

0.88

Kcal / Kg°C

COOLING TEMP°C

67.20

Kcal / Kg°C

FREEZING TEMP°C

-1°C

GOODS OF

FREEZING HEAT°C

Above values may have some specific changes on type of product and desired solution. Contact with ESADPANEL for more.

Maintaining the moisture content of apples in apple cold storage is crucial. During long-term storage, maintaining the apple’s surface without wrinkling, maintaining apple’s market value, and preserving its flavor and texture depends on maintaining this moisture content. The most crucial element of an apple cold room system is picking the right fruits at the right time. Apple producers categorize apples by evaluating numerous parameters, including size, color, defects, and weight. Barcode systems on apples allow consumers to access a wide range of information, including apple origin, field, harvest date, and supplier. Therefore, it is recommended that only perfect apples be used for long-term storage.

It is also crucial to store apples in the correct boxes & crates and avoid crushing them. When necessary, crates with air ducts are highly beneficial for cooling apples. It is crucial that apple cold storage temperatures are maintained between 0°C and 2°C. If you cool your apples too much, they can freeze and harden. Their acidity can deteriorate. If you don’t cool them sufficiently, they can soften and shrivel. Remember, no one wants to eat a soft apple. Therefore, it is crucial to regularly monitor, record, and report apple cold room.

WHAT ESADPANEL OFFERS

As both a manufacturer and a project company, we can design and manufacture turnkey apple cold storage facilities tailored to your needs. We offer our valued customers a long-term, secure food storage system. We deliver turnkey solutions to businesses, which are key components of the food chain, using our own products and team. With global refrigeration after-sales service capabilities, we serve to Africa, Europe, Asia, and the America continents.

WORLDWIDE

SHIPPING

PROJECTS

TURNKEY

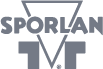

500m2 APPLE COLD ROOM

A cold storage facility is a profitable investment. Especially if you’re skilled in the field. If you have a large space and want to design a 500m² cold room facility to start, here’s a great idea. The technical drawings and 3D design below can help you achieve your dream.

Or, we can design a custom cold storage solution specifically for your existing space.

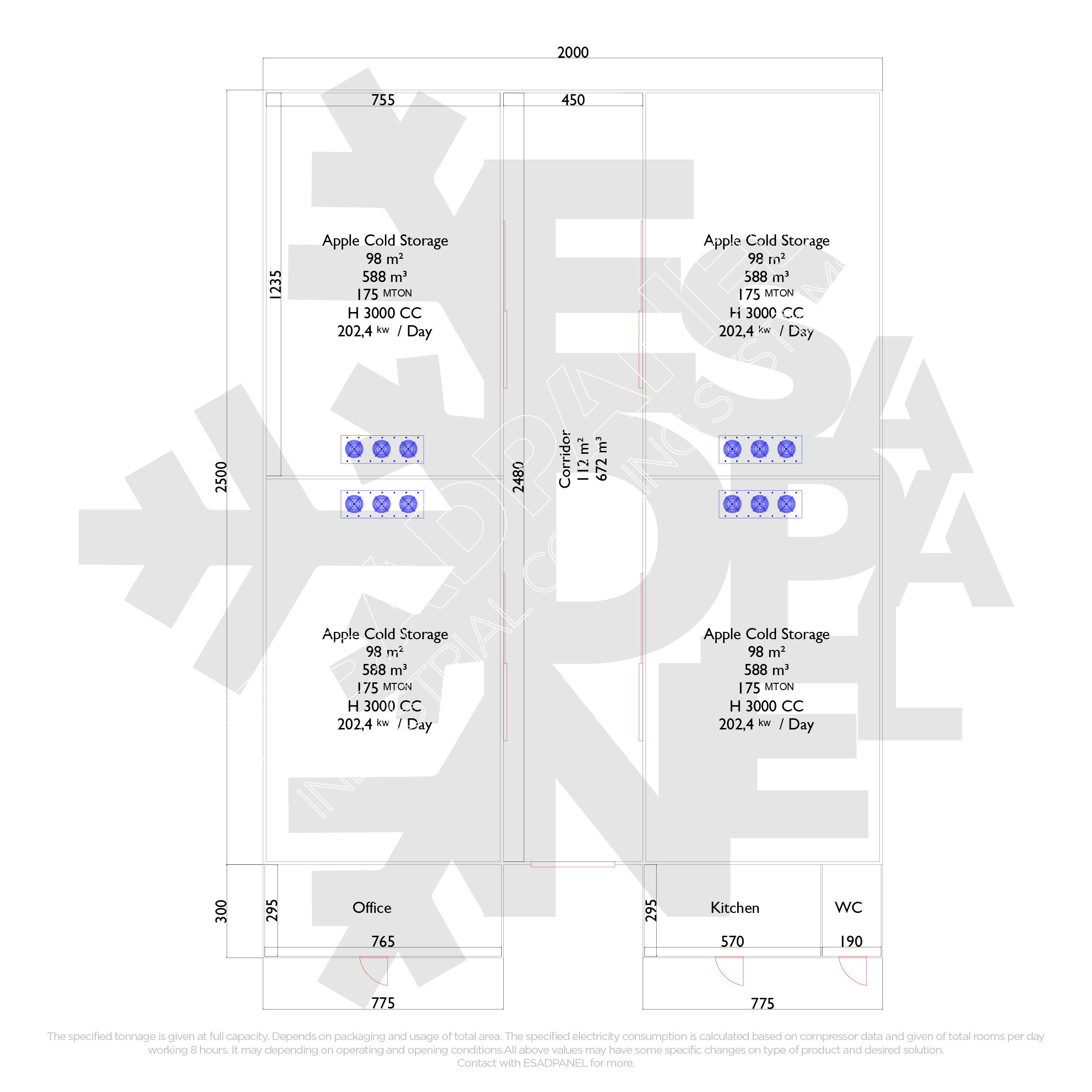

500 M2 APPLE COLD ROOM

2D DRAWING

This is the apple cold room facility with the technical dimensions provided. The apple cold room above contains four different rooms. Each apple cold room has a capacity of 175 metric tons. The average daily electricity consumption is 202,4 kW. Each of these rooms is designed as 98 m² and 588 m³. The design includes a 4.5 m wide corridor for easy movement of loading and unloading equipment such as forklifts and pallet jacks. The facility also includes an office, kitchen, and WC for staff. Of course, there could even be a truck docking area and parking lot at the front. This is within our power to achieve by utilizing the available square meters.

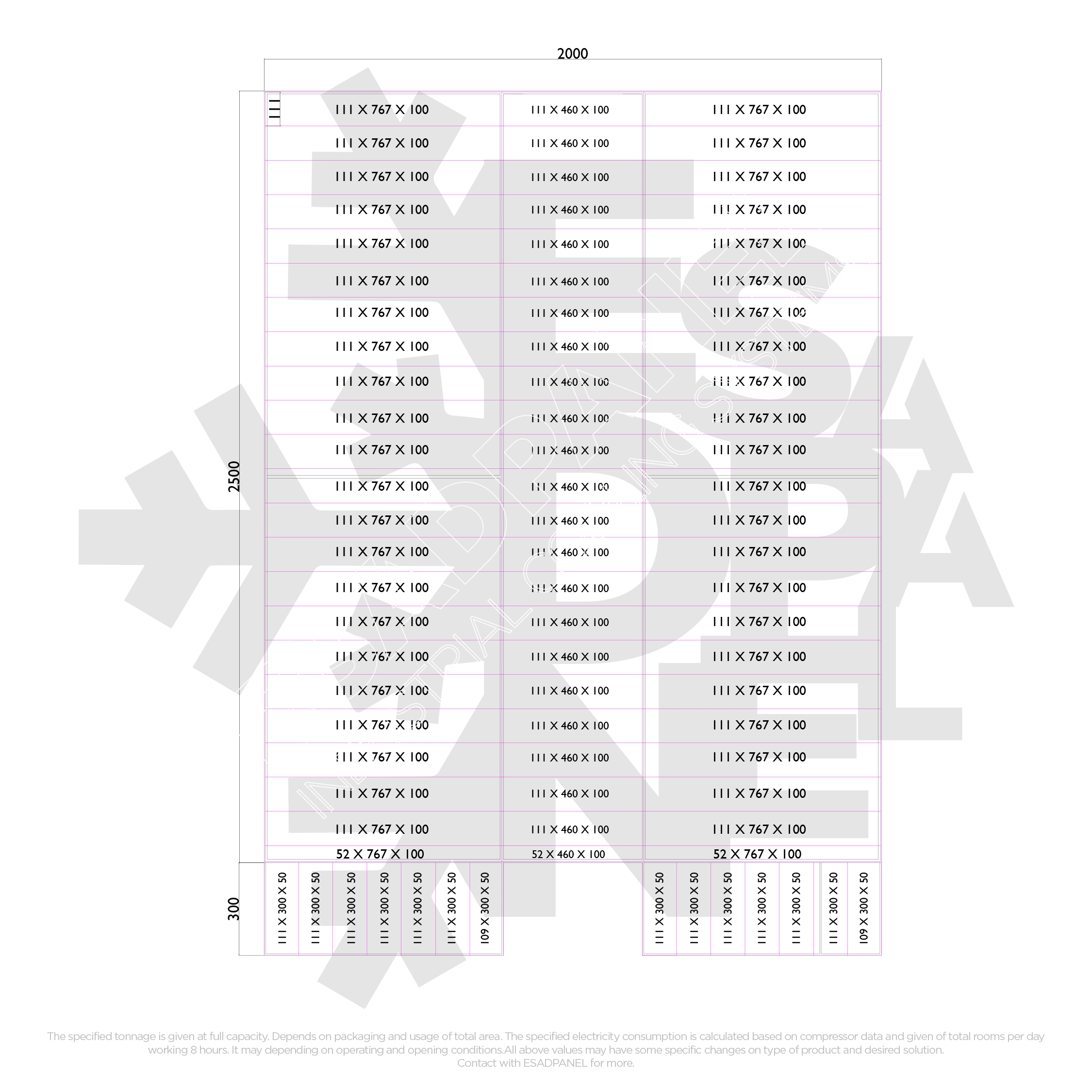

500 M2 APPLE COLD ROOM

3D RENDER

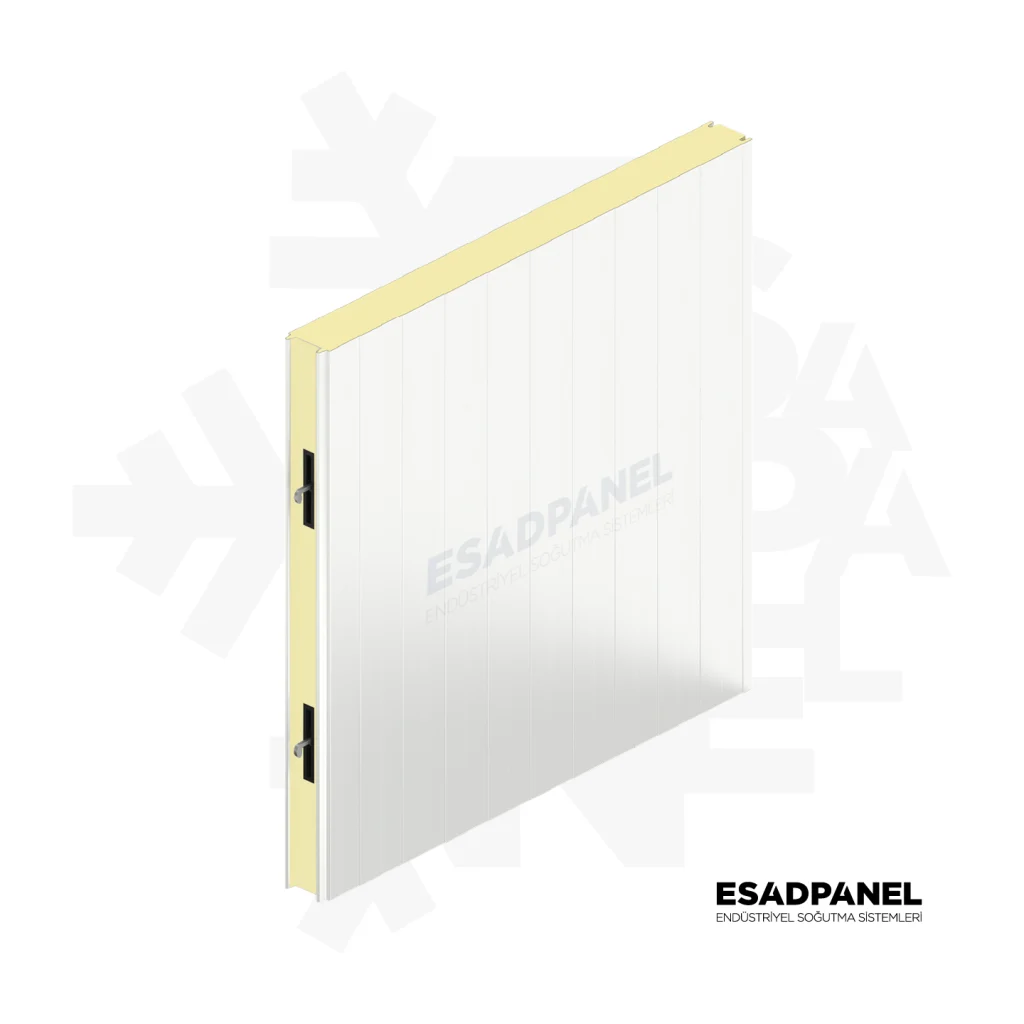

These images also show a 3D rendering of the existing plan. The cold rooms featured in the images are constructed with polyurethane-filled cold room panels and cold storage doors. Panel thicknesses can be customized from 5cm to 20cm, depending on the project. For apple rooms, 8-10cm panels are sufficient. Furthermore, the condenser units and evaporators were specifically selected for apple cold storage. Humidifiers and damper air climate/ventilation systems have created a long-lasting apple cold room capable of storing apples with coverin market value and crispy apples.

2°C

WORKING

TEMPERATURE

700

TONNAGE

CAPACITY

1626

M2 OF

PANELS

BRAND OF

COMPRESSORS

810 kW

CONSUMPTION OF

ENERGY

The specified tonnage is given at full capacity. Depends on packaging and usage of total area. The specified electricity consumption is calculated based on compressor data and given of total rooms per day working 8 hours. It may depending on operating and opening conditions.All above values may have some specific changes on type of product and desired solution. Contact with ESADPANEL for more.

APPLE PROCESSING PLANT

Apple processing facilities are quite large and comprehensive. In these facilities, apples are collected in crates and stored. They are then washed in heated, chlorinated water in washing tanks using conveyor systems. This removes any bacteria, insects, blemishes, and other microorganisms that may be lingering on their surfaces. They are also stripped of wax, which has naturally not been sufficiently dispersed. The protective layer of wax is then reapplied, protecting against potential micro cracks. This ensures greater moisture retention and maximizes market value. Afterward, the apples are sorted by various parameters, such as weight, color, and size, using drying and infrared cameras. They are then shipped to cold storage and, ultimately, to the end consumer.

All contents above are presented for example purposes only.

1000m2 APPLE COLD ROOM

There’s always a bigger option. If you need more tonnage in a cold storage facility, here’s a plan for a larger 1000m² cold room.

Your apples can be stored in these rooms for extended periods, maintaining excellent market value.

We can even design a dedicated office, restroom, kitchen, accounting area, loading area, and parking spaces.

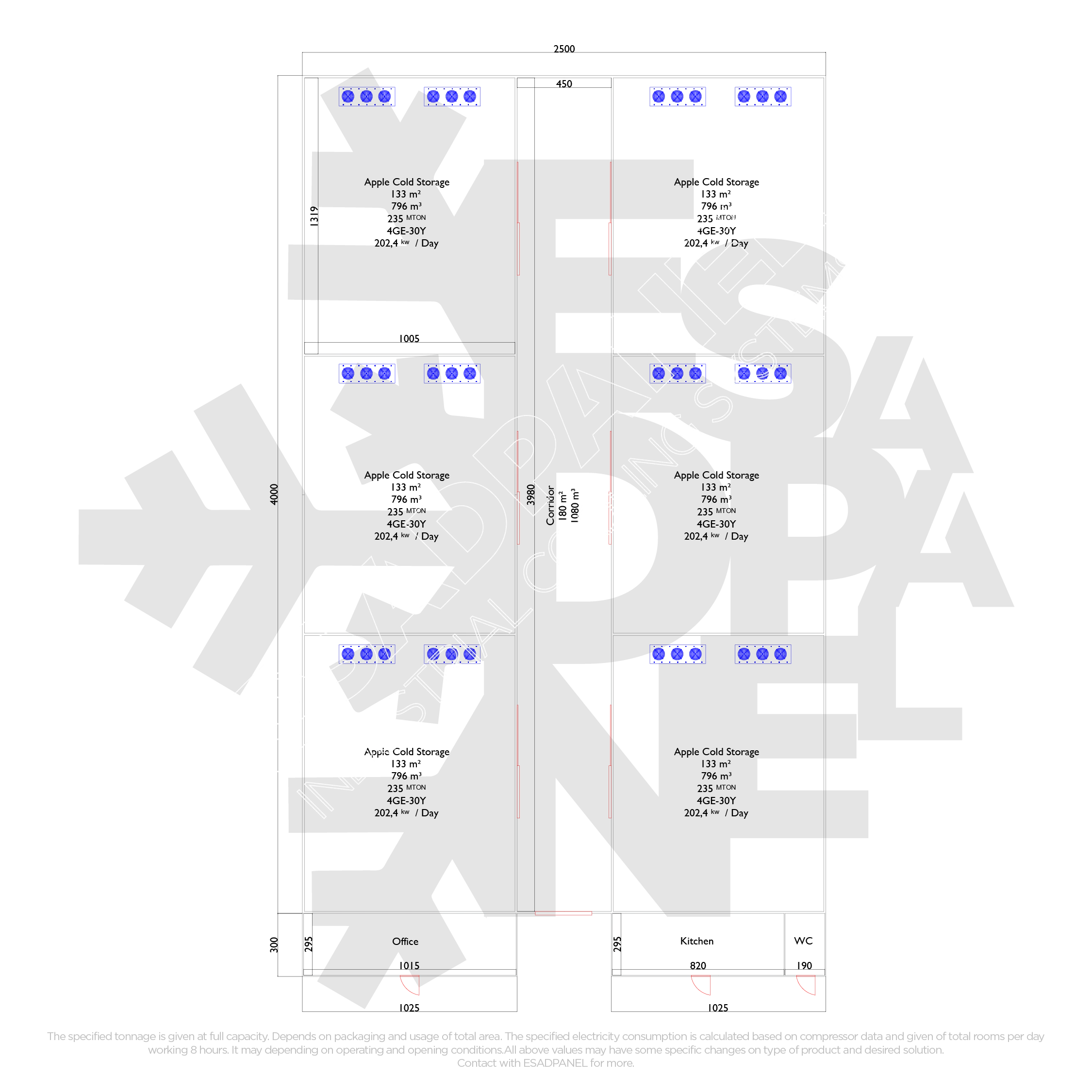

1000M2 APPLE COLD ROOM

2D DRAWING

This is the apple cold room facility with the technical dimensions provided. The apple cold room above contains six different rooms. Each apple cold room has a capacity of 235 metric tons. The average daily electricity consumption is 236 kW. Each of these rooms is designed as 133 m² and 796 m³. The design includes a 4.5 m wide corridor for easy movement of loading and unloading equipment such as forklifts and pallet jacks. The facility also includes an office, kitchen, and WC for staff. Of course, there could even be a truck docking area and parking lot at the front. This is within our power to achieve by utilizing the available square meters.

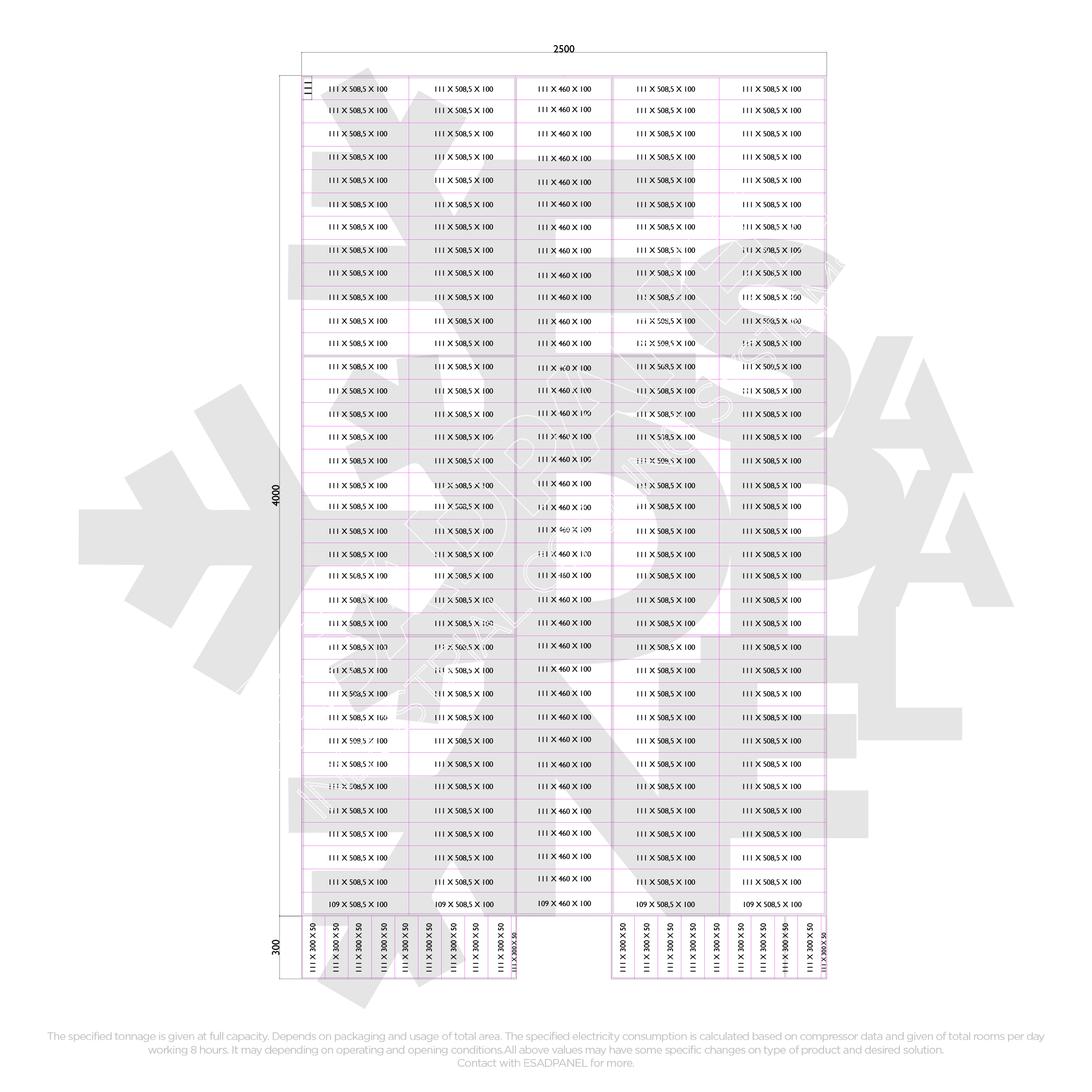

1000M2 APPLE COLD ROOM

3D RENDER

These images also show a 3D rendering of the existing plan. The cold rooms featured in the images are constructed with polyurethane-filled cold room panels and cold storage doors. Panel thicknesses can be customized from 5cm to 20cm, depending on the project. For apple rooms, 8-10cm panels are sufficient. Furthermore, the condenser units and evaporators were specifically selected for apple cold storage. Humidifiers and damper air climate/ventilation systems have created a long-lasting apple cold room capable of storing apples with coverin market value and crispy apples.

2°C

WORKING

TEMPERATURE

1400

TONNAGE

CAPACITY

2643

M2 OF

PANELS

BRAND OF

COMPRESSORS

1215 kw

CONSUMPTION OF

ENERGY

The specified tonnage is given at full capacity. Depends on packaging and usage of total area. The specified electricity consumption is calculated based on compressor data and given of total rooms per day working 8 hours. It may depending on operating and opening conditions.All above values may have some specific changes on type of product and desired solution. Contact with ESADPANEL for more.

WE USE WORLDWIDE MATERIALS

With condenser units designed with components from world-renowned, reliable manufacturers, your cooling system is guaranteed long-term safety. The components we use in our products are available worldwide and are familiar to all refrigeration engineers and technicians.

LESS

GWP

PARTS OF

SPARE

AVAILABILITY OF

SERVICE

FOR MANY

POWER V/PH/HZ

We can design both economical and long-term systems based on the geographic location where the products will be used. We can adjust voltage, phase and hz values across a wide range of voltages, both single-phase and three-phase. We do provide it for USA, Europe and Asian markets too.

We also offer refrigerant options. While low-GWP gases can be used, common gases are also among our options.

SMALLER / LARGER

Larger or smaller, it doesn’t matter. A 10m³ cold room or a 10,000m³ cold storage is beyond the capacity of this factory. ESADPANEL is always at your service, providing the key to production with the features you desire and open to millions of customizations. Contact us for the design, production, and turnkey delivery of your cold storage facilities.